Wind energy

The trend in wind energy is to reduce production costs per MWh of electricity produced while maintaining the quality and reliability of power plants. The innovative ZKL main rotor bearing solutions for different main shaft bearings arrangement allow you to remain competitive and efficient at the same time.

Purchase ZKL bearings from authorized distributors

Find a distributor

Find a distributor

Technical support:

ZKL spherical roller bearings for the main rotors of wind turbines

Spherical roller bearings for main rotors designed for demanding wind farm operating conditions.

Properties:

|

Advantages:

|

ZKL advanced spherical roller bearings for the main rotors of wind turbines

Advanced spherical roller bearings are optimized according to the specific operating conditions of wind turbines and take into account the special requirements of the customer.

Properties:

|

Advantages:

|

ZKL single-row tapered roller bearings for the main rotors of wind turbines

The design of the bearings is adapted to the requirements of mounting in a housing with an optimized unique cage solution.

Properties:

|

Advantages:

|

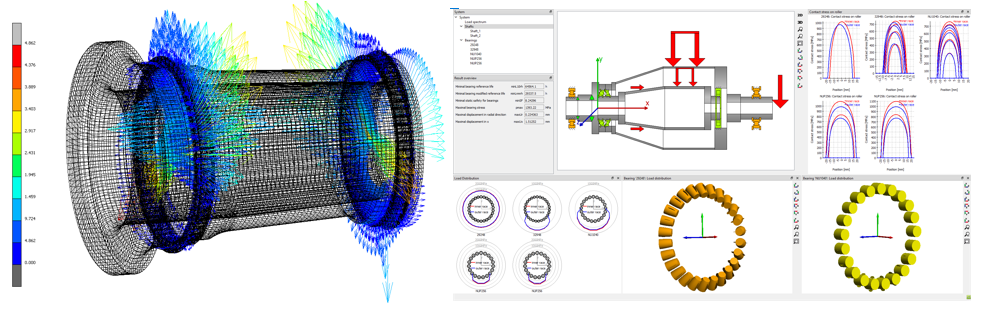

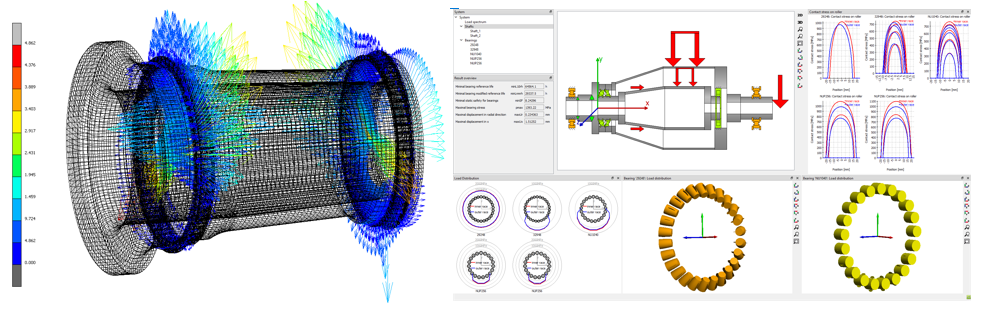

Calculations and simulations

We design bearings and suitable bearing arrangement with regard to specific loads and operating conditions of customers with regard to cost minimization. The actual production and delivery of bearings to wind turbines is preceded by conceptual project management. It includes calculations of bearing durability and contact stresses based on data simulating the actual operation of the power plant.